Project Info

COMPLETE

Project Title

Project Title

Project Title

Project Title

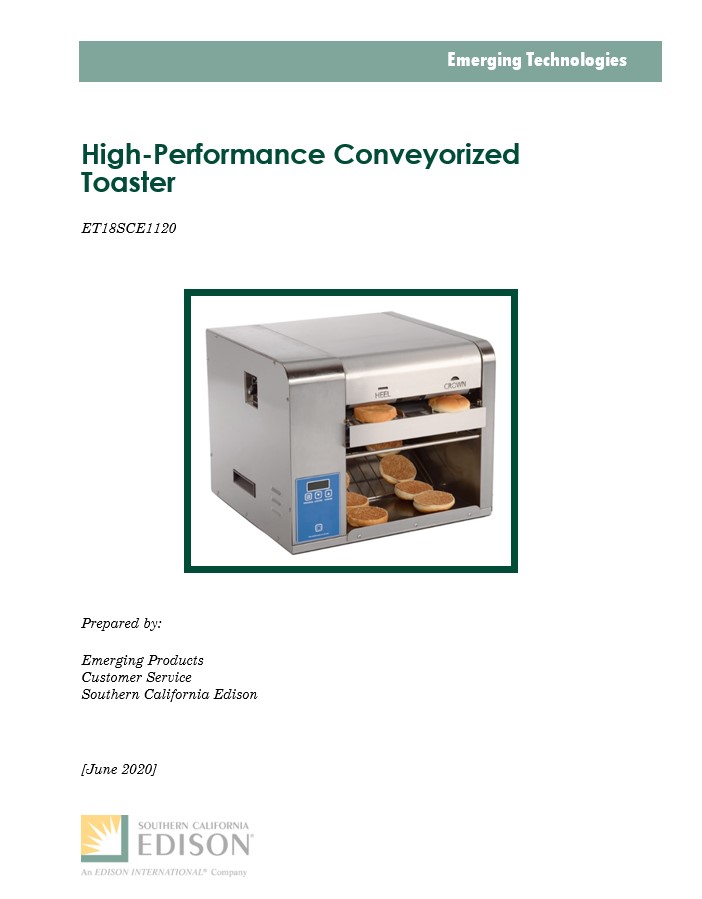

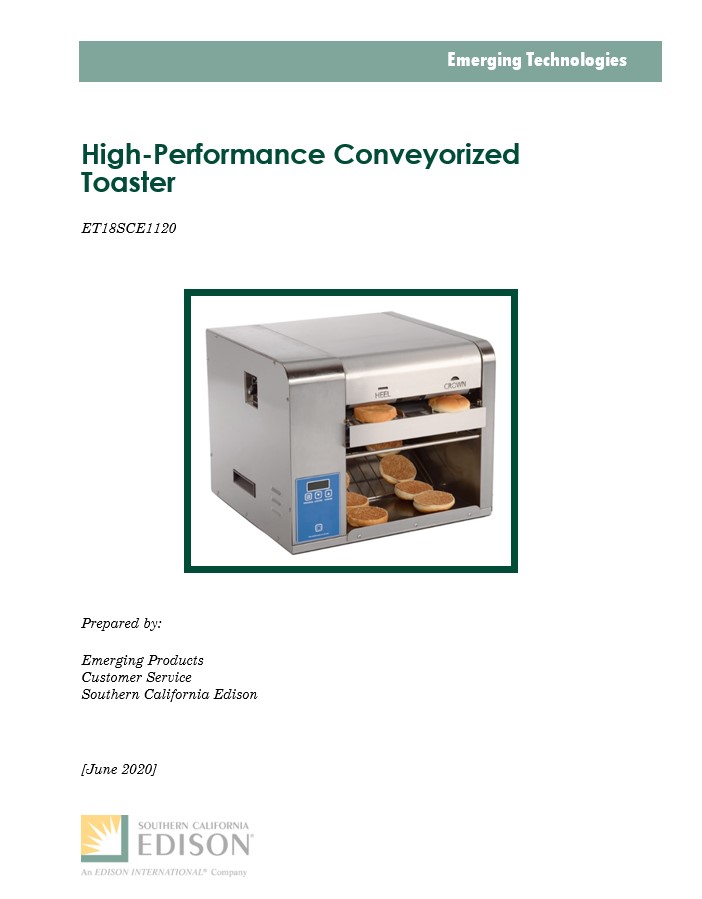

High Performance Conveyorized Toaster

Project Number ET18SCE1120 Organization SCE End-use Cooking Equipment Sector Commercial Project Year(s) 2018 - 2020Description

High performance conveyorized toaster used by fast food restaurants especially. Predicted performance is to reduced energy for toasting buns and english muffins is 2/3 of incumbent technology. Market study, baseline performance and field testing of the high performance units.

Project Report Document

Loading PDF Preview...